Ingxowa yokucoca inayilonikunye nengxowa yokucoca i-polyester iyahluka kwizinto eziphathekayo, ukwakhiwa, kunye nokusebenza. Uhlobo ngalunye lubonelela ngeenzuzo ezizodwa zokucoca ulwelo. Ukukhetha ingxowa echanekileyo yokucoca imidiya ichaphazela ukusebenza kakuhle kokucoca kunye neziphumo zexesha elide. Ukhetho olufanelekileyo lunceda abasebenzisi ukuba bafezekise isiphumo esilungileyo sosetyenziso lwabo oluthile. I-Bag filter media inokuphucula umgangatho wemveliso kunye nokuthembeka kwenkqubo.

Yintoni ibhegi yesihluzi seNayiloni

IsiXhobo seNylon yesihluzi kunye noKwakha

Ibhegi yokucoca inayiloni igqame kuhluzo lwamashishini ngenxa yeempawu zayo ezizodwa kunye nolwakhiwo. Abavelisi basebenzisa i-nylon monofilament mesh ekumgangatho ophezulu ukwenza ezi ngxowa. Lo mesh ubonisa ukuluka okuchanekileyo, okuqinisekisa ubungakanani bepore obungaguqukiyo kunye nokuhluzwa okuthembekileyo. Ulwakhiwo lunika ukomelela okugqwesileyo kunye nokuqina, okwenza ibhegi yokucoca inayiloni ilungele iimeko ezibango.

Le theyibhile ilandelayo iqaqambisa iimpawu eziphambili zemathiriyeli ezahlula iingxowa zokucoca inayiloni kwezinye iindidi:

| Ipropati | Iinkcukacha |

|---|---|

| Ukusetyenziswa ngokufanelekileyo | Uhluzo lweMichiza yezoQoqosho kunye neMild Media |

| Iyahambelana ne | Izinyibilikisi ze-Organic, i-oyile, ii-Microorganisms, iialkali |

| Ayihambelani ne | Ii-Agents ze-Oxidizing, i-Mineral Acids, i-Inorganic Acids |

| Umlinganiselo wobushushu | 0-325°F |

| Ukukala kweMicron | 5µm ukuya kwi-1,000µm |

| Iintlobo zokwakha | Umnatha weNayiloni weMonofilament, uMnatha weNylon oyi-Multifilament |

| Ezinye Iimpawu eziphambili | I-FDA-iBanga lokuTya, eliCocayo / liSebenziswa kwakhona, Amandla okuqina okuPhezulu |

Iingxowa zesihluzi zenayiloni zixhathisa ukukrazuka kunye nokugruzuka. Lo mgangatho ubenza balungele ukuhluzwa kwamashishini apho iimeko ezibuhlungu zihlala zisenzeka. Umnatha olukiweyo ngokuqinileyo uvumela amazinga aphezulu okuhamba, okuphucula ukusebenza kakuhle kwiinkqubo ezininzi zokucoca kumashishini.

Iimpawu eziphambili kunye neeNzuzo

Iingxowa zokucoca inayiloni zibonelela ngezinto ezininzi kunye nezibonelelo ezizenza zibe lukhetho olukhethwayo kuhluzo lwamashishini:

- Amandla aphezulu kunye nokuqina kwenkxaso yokusetyenziswa kwexesha elide.

- I-abrasion efanelekileyo kunye nokumelana nokunxiba kunceda ukugcina ukusebenza kwiindawo ezinzima.

- Uzinzo olugqwesileyo lweekhemikhali kunye ne-thermal luvumela ukusetyenziswa kwi-moderate exposure yekhemikhali.

- Ukukhuhlana okuphantsi kunye neempawu zomgangatho ogudileyo ziqinisekisa ukuhamba kwamanzi okusebenzayo.

- Ukuguquguquka kwezicelo kubandakanya ukucocwa kwamanzi, ukusetyenzwa kweekhemikhali, kunye nokuveliswa kwemizi-mveliso.

Abavelisi abafana ne-Precision Filtration babonelela ngeengxowa zesihluzi senayiloni ngokomgangatho oqhelekileyo kunye nobukhulu besiko. Iinketho ezininzi zokutywinwa, njengeRing Top kunye nePlastiki Flange, ukwandisa ukuhambelana nezindlu ezahlukeneyo. Ezi ngxowa ziphinda zisebenziseke, ezinceda ukunciphisa iindleko ngokuhamba kwexesha.

Iingxowa zokucoca inayiloni nazo zidibana nemigaqo ye-FDA yokutya kunye nezicelo zesiselo. Bafumana uvavanyo olungqongqo lokungena komoya kunye nokomelela. Ingxowa nganye itywinwe ngokukodwa kwipakethe yokukhusela ukugcina ubunyulu kunye nokuthintela ukungcoliseka.

Ingcebiso: Iingxowa zesihluzi zenayiloni zisebenza kakuhle kuzo zombini ulwelo oluphezulu lwe-viscous kunye nemisebenzi yokuhluza jikelele kwimizi-mveliso. Ukusetyenziswa kwakhona kunye nokuthobela imigangatho yebakala lokutya kubenza babe lukhetho oluthembekileyo kumashishini amaninzi.

Yintoni iPolyester Filter Bag

Izinto zePolyester Filter Bag kunye noKwakha

Iingxowa zokucoca i-polyester zidlala indima ebalulekileyo kuhluzo lwamashishini. Abavelisi basebenzisa ii-polyester fibers ukudala ezi ngxowa, ezibonelela ngokulinganisela kwamandla kunye nokuguquguquka. Inkqubo yokwakha ibandakanya ukuluka okanye ukuphola imicu yepolyester ibe ilaphu elomeleleyo. Le ndlela ivelisa ingxowa yokucoca enokumelana namazinga aphezulu okuhamba kunye noxinzelelo ngaphandle kokukrazula.

Iingxowa zokucoca i-polyester zibonisa ukuxhathisa okugqwesileyo kwi-abrasion. Bagcina imilo kunye nobukhulu babo nangona bevezwe kumaqondo aphezulu. Uninzi lweengxowa zokucoca i-polyester zisebenza kumaqondo obushushu ukuya kuma-275 ° F, kunye nokuhamba okufutshane okufika kwi-300 ° F. Ezi ngxowa zisebenza kakuhle kwiimeko ezomileyo kunye ne-acids ephantsi kunye ne-alkalis. Azikhuthazwa kwiindawo ezifumileyo okanye ezifumileyo kakhulu.

Le theyibhile ilandelayo ishwankathela iimpawu eziphambili zeengxowa zokucoca i-polyester:

| Uphawu | Inkcazo |

|---|---|

| UkuFaneka koHlelo | Iphezulu, isebenzayo kwiincinci ezincinci kunye nothuli |

| Tensile strength | Okugqwesileyo, ukumelana nokukrazula phantsi koxinzelelo |

| Ukunyangwa kweAbrasion | Okugqwesileyo, ukumelana nokunxiba ekusetyenzisweni kwamashishini |

| Uzinzo lweDimensional | Igcina imilo phantsi kobushushu, i-shrinkage ephantsi |

| Ukucoceka ngokulula | Inokucocwa kwaye isetyenziswe kwakhona, kodwa ukucocwa ngokuphindaphindiweyo kunokuchaphazela ukusebenza |

| Ubomi Benkonzo | Ixesha elide, linciphisa isidingo sokutshintshwa rhoqo |

| Isondlo | Kulula, kunciphisa iindleko zokulondoloza |

| Ukuguquguquka | Ifumaneka ngeesayizi ezininzi kunye neemilo |

| Ukusebenza kweendleko | Iyafikeleleka xa ithelekiswa nezinye izixhobo |

Qaphela: Iingxowa zokucoca iipolyester ziyafumaneka ngokubanzi kwaye zibonelela ngesisombululo esinexabiso eliphantsi kumashishini amaninzi.

Iimpawu eziphambili kunye neeNzuzo

Iingxowa zokucoca i-polyester zibonelela ngezinto ezininzi ezibalulekileyo kunye neenzuzo. Ulwakhiwo lwabo lwefayibha ekhululekileyo lunyusa umthamo wokubamba ukungcola, okuphucula ukusebenza kakuhle kokucoca. Ezi ngxowa zisebenzisa indlela yokuhluza enamanqanaba amabini. Ukuhluzwa komphezulu kubamba amasuntswana amakhulu, ngelixa ukuhluza ubunzulu kubambe izingcoliso ezicolekileyo.

- Umthamo wokungcola ophuculweyo uxhasa ukuhluzwa okusebenzayo.

- Indlela yokuhluza kabini iphucula ukususwa kwamasuntswana.

- Ukuqina phantsi koxinzelelo kuqinisekisa ukusebenza okuhambelanayo.

- Amandla okuqina okugqwesileyo kunye nokumelana ne-oxidation kwandisa ixesha lokuphila.

- Ukugcinwa lula kunceda ukunciphisa iindleko zokusebenza.

Iingxowa zokucoca i-polyester ziyilelwe ukusetyenziswa kanye. Ukucoca kunye nokusetyenziswa kwakhona kwezi ngxowa kungonakalisa izinto eziphathekayo, ezinokuchaphazela ukusebenza kokucoca. Umonakalo unokubangela ukuba imingxunya eyandisiweyo okanye inciphe, nto leyo ekhokelela ekufakeni iplagi ngokukhawuleza okanye kuncitshiswe ukusebenza kakuhle.

Ingcebiso: Iingxowa zokucoca i-polyester zisebenza kakuhle kwiindawo ezomileyo kwaye zibonelela ngokucoca okuthembekileyo kuthuli, amasuntswana amahle, kunye nokusetyenziswa kweshishini.

Iiyantlukwano eziphambili kwiMedia yesihluzi seBag

UkuFaneka koHlelo

Ukusebenza kakuhle kohluzo kudlala indima ebalulekileyo ekumiseleni ukusebenza kakuhle kwemithombo yeendaba zokucoca. Iingxowa zokucoca i-polyester zigqwesa ekususeni i-particulate ecolekileyo, ukubamba amasuntswana amancinci njenge-1 micron. Iingxowa zokucoca inayiloni zisebenza kakuhle ngamasuntswana amakhulu, zizenza zilungele usetyenziso olungadingi ukuhluzwa okuphezulu. Le theyibhile ilandelayo ithelekisa ukusebenza kakuhle kohluzo kunye noluhlu lobungakanani bamasuntswana kuzo zombini izixhobo:

| Izinto eziphathekayo | UkuFaneka koHlelo | Uluhlu lobungakanani beNcam |

|---|---|---|

| Ipolyester | Kugqwesileyo (ukuya kuthi ga kwi-1 micron) | I-1 ukuya kwi-800 microns |

| Inayiloni | Kuhle (amasuntswana amakhulu) | I-1 ukuya kwi-100 microns |

Iingxowa zesihluzi sePolyester zibonelela ngobuchule obuphezulu ekususweni kwamasuntswana, nto leyo iyimfuneko kumashishini afuna iziphumo ezizezona zilungileyo zokuhluza. Iingxowa zokucoca inayiloni zibonelela ngobuchule obuthembekileyo kwimisebenzi yokucoca ngokubanzi, ngakumbi xa kufuneka umthamo omkhulu wokubamba ubumdaka. Zombini ezi ntlobo zemithombo yeendaba zokucoca ingxowa zinegalelo ekususweni kongcoliseko, kodwa ipolyester ibalasele kwizicelo ezifuna ukusebenza kakuhle kokucoca.

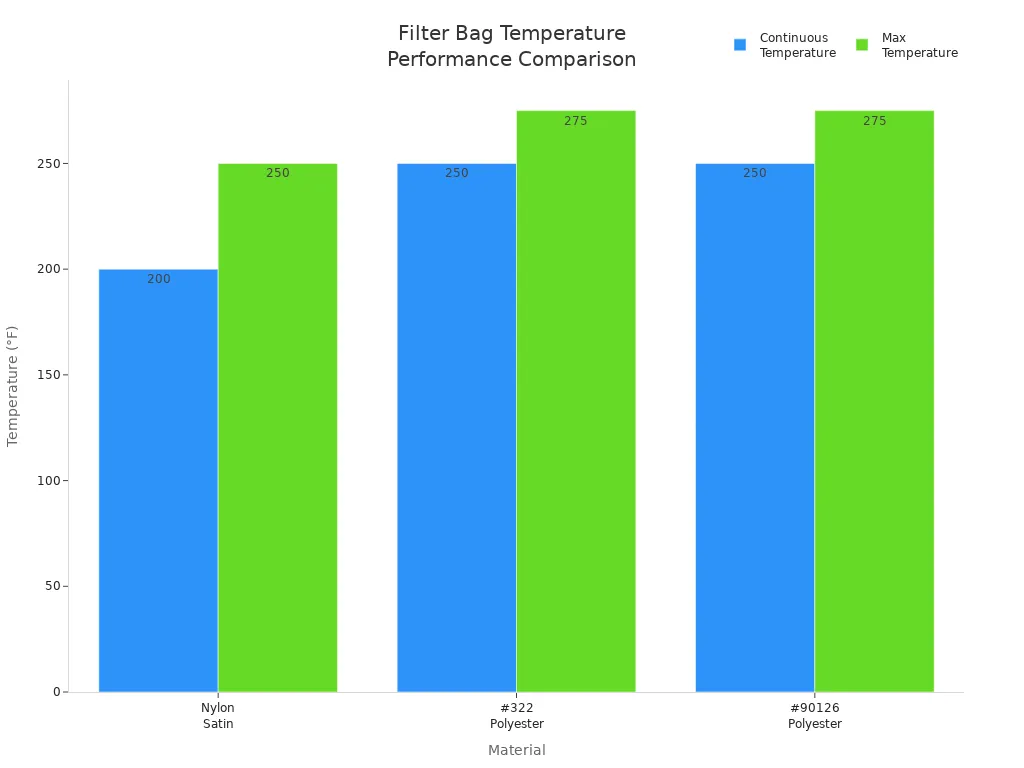

Iqondo lobushushu kunye nokumelana neMichiza

Ubushushu kunye nokuhambelana kweekhemikhali zizinto ezibalulekileyo xa ukhetha i-bag filter media. Iingxowa zokucoca iPolyester zimelana nobushushu obuphezulu, zisebenza ngokuqhubekayo kwi-250°F kwaye zifikelela kubuninzi obungama-275°F. Iingxowa zokucoca inayiloni zisebenza kakuhle ukuya kuthi ga kwi-200°F ukuze ziqhubeke zisetyenziswa, ezinobuninzi obungama-250°F. Itshathi engezantsi ibonisa umlinganiselo wobushushu wazo zombini imathiriyeli:

Iingxowa zokucoca i-polyester zisebenza kakuhle kufakelo lobushushu elomileyo. Kwiindawo ezifumileyo, ngakumbi kumaqondo obushushu aphakathi kwe-160 ° F kunye ne-210 ° F, i-polyester inokufumana i-hydrolysis, enokwenza buthathaka ilaphu. Iingxowa zokucoca i-nayiloni zinika ukuhambelana okuqinileyo kweekhemikhali kunye ne-acids ezibuthathaka kunye ne-alkali, kodwa azikhuthazwa kwii-acids ezinamandla okanye i-oxidizing agents. Iingxowa zokucoca i-polyester zibonisa ukuhambelana kakuhle kweekhemikhali kunye neeasidi ezininzi, zizenza zilungele uluhlu olubanzi lwezicelo zemizi-mveliso.

Ingcebiso: Soloko uqwalasela ukuhambelana kweekhemikhali kunye neemfuno zobushushu benkqubo yakho phambi kokukhetha ingxowa yeendaba zokucoca.

Ukuqina kunye Nobomi obude

Ukuqina kunye nobomi benkonzo eyandisiweyo yingqwalasela ephambili ye-bag filter media. Iingxowa zesihluzi senayiloni zibonakalisa ukomelela kwe-mesh ephezulu kwaye zixhathise iiasidi ezibuthathaka kunye neealkali, ezinegalelo kubomi babo benkonzo eyandisiweyo. Iingxowa zokucoca i-polyester nazo zibonelela ngokuchaneka kakuhle kokunxiba kunye nokukrazula, kodwa amandla azo e-mesh asezantsi kunenylon. Itheyibhile engezantsi iqaqambisa uqikelelo lokuqina kwazo zombini imathiriyeli:

| Ipropati | Inayiloni | Ipolyester |

|---|---|---|

| Ukuchasana neeasidi ezibuthathaka | Uphakamileyo | Ukuxhathisa |

| Ukuchasana neeasidi ezinamandla | Uhlaselwe | Uhlaselo olucothayo |

| Ukumelana nee-alkali ezibuthathaka | Uphakamileyo | Ukuxhathisa |

| Ukuchasana neealkali ezinamandla | Ukuxhathisa | Uhlaselwe |

| Amandla eMesh | Omelele ngakumbi | Ubuthathaka |

| Ubushushu obuncomekayo obukhulu | 350°F | 250°F |

Iingxowa zokucoca inayiloni zinceda ukunciphisa iindleko zokusebenza ngokwandisa ixesha phakathi kweenguqu zokucoca. Ubomi babo obude kunye nokuhambelana kweekhemikhali kwenza ukuba kube yinto ekhethwayo kwiinkqubo ezininzi zoshishino. Ukugcinwa ngokufanelekileyo kwe-bag filter media kubalulekile ukuphepha umonakalo wenkqubo kunye nokungasebenzi kakuhle. Iingxowa zokucoca i-polyester nazo zibonelela ngokuzinzileyo, kodwa ukucocwa okuphindaphindiweyo kunokuchaphazela ukusebenza kwazo kunye nokusebenza kwazo.

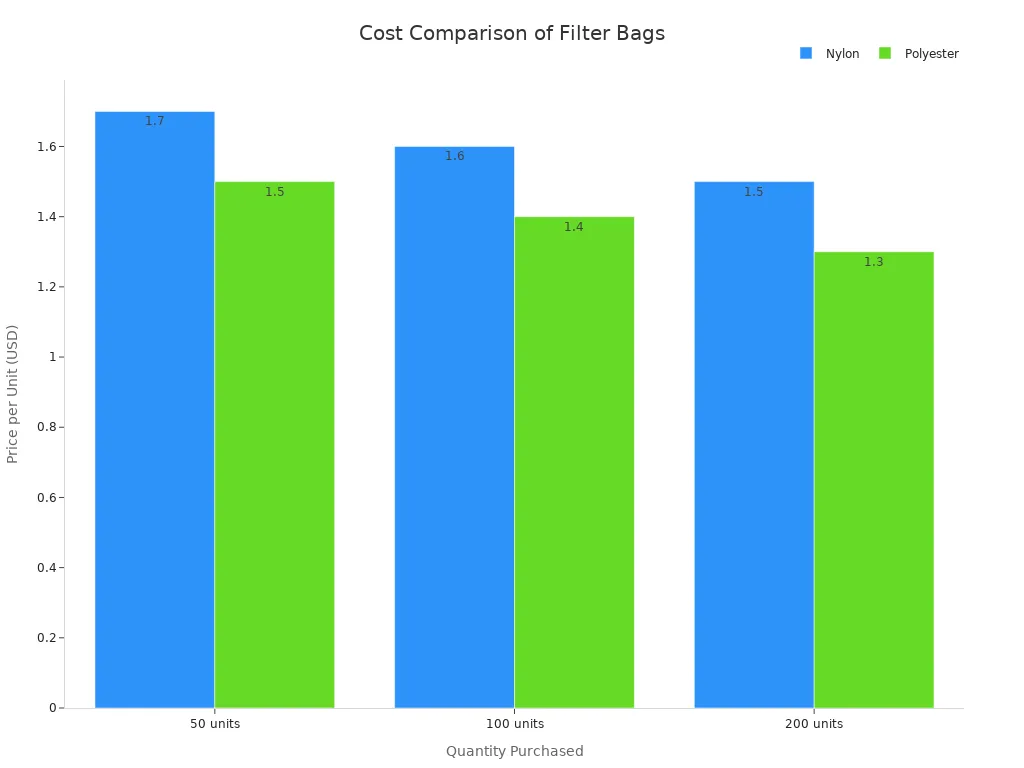

Uthelekiso lweendleko

Iindleko yinto ebalulekileyo xa kuvavanywa ingxowa yeendaba zokucoca kusetyenziso lwamashishini. Iingxowa zokucoca ipolyester zibonelela ngexabiso eliphantsi ngeyunithi nganye xa kuthelekiswa neengxowa zokucoca inayiloni, ngakumbi xa zithengwe ngobuninzi. Itheyibhile engezantsi ibonisa umahluko wamaxabiso kwizixa ezahlukeneyo:

| Uhlobo lwengxowa yesihluzi | Ubungakanani | Ixabiso ngeYunithi nganye |

|---|---|---|

| Inayiloni | 50 | $1,700 |

| Inayiloni | 100 | $1,600 |

| Inayiloni | 200 | $1,500 |

| Ipolyester | 50 | $1,500 |

| Ipolyester | 100 | $1.400 |

| Ipolyester | 200 | $1,300 |

Iingxowa zokucoca inayiloni zibonelela ngexabiso elibalaseleyo lemali ngenxa yokusebenza kwazo okuphezulu kunye nokuqina. Banciphisa iimfuno zokulondoloza kwaye bancede ukunciphisa iindleko zokusebenza. Iingxowa zokucoca i-polyester zibonelela ngokufikeleleka kunye nokusebenza kakuhle, nto leyo ezenza zibe lukhetho oludumileyo kumashishini amaninzi. Zombini iintlobo zemithombo yeendaba zokucoca ingxowa zibonelela ngeziphumo ezizezona zilungileyo zokuhluza, kodwa isigqibo sokugqibela sihlala sixhomekeke kuhlahlo lwabiwo-mali, isicelo, kunye nobomi benkonzo obandisiweyo obunqwenelekayo.

Qaphela: Ukukhetha isikhwama esilungileyo seendaba zokucoca kubandakanya ukulinganisa ukusebenza kakuhle kokucoca, ukuhambelana kweekhemikhali, ukuqina, kunye neendleko zokufikelela esona siphumo silungileyo kwinkqubo yakho yokucoca.

Ukufaneleka kweSicelo kunye nokuSetyenziswa kweSihluzi soMqokeleli wothuli

Eyona nto iSetyenziswayo kwiiBagi zeNylon yesihluzi

Iingxowa zokucoca inayiloni zinceda amashishini amaninzi ngenxa yamandla azo kunye nokuguquguquka. Iinkampani zisebenzisa i-bag filter media eyenziwe kwi-nylon kuhluzo lwamanzi, ukuhluzwa komoya, kunye nokuhluzwa kwamashishini. Icandelo lokutya nesiselo lixhomekeke kwiingxowa zokucoca inayiloni ukuthotyelwa nokhuseleko. Le theyibhile ilandelayo ibonisa izicelo eziqhelekileyo:

| Uhlobo lwesicelo | Inkcazo |

|---|---|

| Ukuhluzwa kwamanzi | Isusa ukungcola kwimithombo yamanzi. |

| Ukuhluzwa koMoya | Amasuntswana omgibe kwiinkqubo zokucoca umoya. |

| Ukuhluzwa kwamashishini | Ukwahlula izinto eziqinileyo kulwelo olukwimveliso. |

| Ukuhluzwa kokutya kunye nesiselo | Uqinisekisa ukhuseleko ekulungisweni kokutya kunye nemveliso yesiselo. |

Amashishini afana namayeza, i-biotechnology, kunye nokulungiswa kweekhemikhali bakhetha i-nayiloni yesihluzi sengxowa yeendaba kwimisebenzi efana nokuvala inzala kunye nokucaciswa. Iingxowa zokucoca i-nayiloni zikwagqwesa kwiinkqubo zengxowa yokucoca uthuli, apho ukuxhathisa kwe-abrasion kunye namandla oomatshini kunciphisa ukuphindaphindeka kokutshintshwa. Ukuhambelana kwabo kweekhemikhali kunye nee-alkali kunye neekhemikhali eziphilayo kubenza bathembeke kwiindawo ezinomngeni.

Iingxowa zokucoca inayiloni zibonelela ngokusulungekileyo okuphezulu, ukuqina, kunye nokugcinwa lula. Basusa iibhaktheriya kunye ne-microorganisms, eziyimfuneko ekukhuseleni ukutya.

Eyona nto isetyenziswayo kwiingxowa zesihluzi sePolyester

Iingxowa zokucoca iPolyester zibonelela ngokucocwa okusebenzayo kumashishini ekhemikhali, kumayeza, nakumashishini epetrochemical. Iinkampani zisebenzisa le ngxowa yeendaba zokucoca ukucoca iikhemikhali ezinobundlobongela, izinyibilikisi, kunye neoyile. Itheyibhile engezantsi igxininisa usetyenziso oluqhelekileyo:

| Ishishini | Inkcazo yesicelo |

|---|---|

| Ishishini lemichiza | Ukuhluzwa kweekhemikhali kunye nezinyibilikisi. |

| Ishishini lezamayeza | Ukuhluza ulwelo ukwenzela ukucoceka kwemveliso. |

| Ishishini lokutya neziselo | Ukuhluzwa kweoli kunye neesyrups. |

| Unyango lwamanzi | Ukuhluzwa kwamanzi amdaka ukususa ungcoliseko. |

| Ishishini lePetrokhemikhali | Ukucoca iimveliso zepetroleum kunye namafutha. |

Imithombo yeendaba yokucoca ingxowa yepolyester iqhuba kakuhle kwindawo eyomileyo kwaye ibonelela ngokumelana ne-UV. Ifanelana nemoto, i-aerospace, kunye nezicelo zokucocwa kwamanzi amdaka. Iingxowa zokucoca i-polyester ziphatha amasuntswana owomileyo kunye nothuli ngokufanelekileyo, zizenza zibe lukhetho oludumileyo kwiinkqubo ezininzi zokuqokelela uthuli.

Ukukhetha Ingxowa yesihluzi esiLungileyo

Ukukhetha ingxowa yeendaba ezilungileyo zokucoca kuxhomekeke kwizinto ezininzi. Abasebenzisi kufuneka baqwalasele iimfuno zokuhluza, iimeko zokusingqongileyo, kunye neemfuno zokulondolozwa. Itheyibhile engezantsi ithelekisa iimpawu zenayiloni kunye nepolyester:

| Umba | Iimpawu zeNayiloni | Iimpawu zePolyester |

|---|---|---|

| Iimfuno zokuhluza | Uphatha amasuntswana aqinileyo okanye abukhali | Ukuphatha amaqhekeza omileyo kunye nothuli kakuhle |

| Iimeko zokusingqongileyo | Ukuqina okuphezulu, ukuvezwa kweekhemikhali okuphakathi | Ukhuseleko oluhle lokufuma, ukuxhathisa kwe-UV |

| ULondolozo kunye neeNdleko | Isenokufuna inkathalo eyodwa | Ihlala ixesha elide ngokucoca okulula |

Ukukhetha ingxowa yeendaba ezilungileyo zokucoca kuqinisekisa ukusebenza ngokugqibeleleyo kunye nokonga kweendleko. Iingxowa zesihluzi senayiloni zilungele imeko-bume efunekayo kunye neenkqubo ezibalulekileyo. Iingxowa zesihluzi sePolyester zisebenza ngcono kuhluzo jikelele kunye nokuqokelela uthuli. Iinkampani kufuneka zitshatise ingxowa yeendaba zokucoca kwisicelo sabo esithile kunye nokusingqongileyo ukuze ufumane iziphumo ezingcono.

Ingcebiso: Soloko uvavanya iimfuno zenkqubo kunye neemeko zokusingqongileyo phambi kokuba ukhethe ingxowa yeendaba ezilungileyo zokucoca.

Iingxowa zokucoca inayiloni kunye nepolyester ziyahluka kwizinto eziphathekayo, ukuqina, kunye nokusebenza kakuhle kokucoca. Inayiloni ifanela ulwelo lwe-viscous kwaye idibana nemigangatho ye-FDA yokhuseleko lokutya. I-polyester isebenza kakuhle kuhluzo oluqhelekileyo lolwelo kunye neendawo ezomileyo. Iingcali zokuhluza zicebisa ukuba zithathele ingqalelo ezi khrayitheriya:

| Iikhrayitheriya | Inkcazo |

|---|---|

| Iimpawu zeNcam | Ubungakanani kunye nohlobo lwamasuntswana aza kususwa |

| Iimeko zeNkqubo | Izinga lokuhamba, uxinzelelo, kunye nobushushu |

| Iindidi zemidiya yesihluzi | Ukuhambelana kwezinto kunye nesicelo |

| Isihluzi seZindlu | Ukufaneleka kwiimfuno zenkqubo ethile |

Ukukhetha ingxowa yokucoca elungileyo kuthetha ukuvavanya iimfuno zosetyenziso, okusingqongileyo, kunye nohlahlo lwabiwo-mali. Umgangatho wemveliso kunye nokuthotyelwa kokulawula kuqinisekisa ukuhluzwa okukhuselekileyo nokusebenzayo.

FAQ

Ngowuphi umahluko omkhulu phakathi kweengxowa zokucoca inayiloni kunye nepolyester?

Iingxowa zokucoca inayiloni zisebenzisa i-monofilament mesh ukomelela kunye nokuqina. Iingxowa zesihluzi sePolyester zisebenzisa iintsinga ezilukiweyo okanye ezisikiweyo ukuze zibe bhetyebhetye kunye nokuhluza amasuntswana amahle. Isixhobo ngasinye sihambelana neemfuno ezahlukeneyo zokuhluza.

Ingaba iingxowa zokucoca inayiloni zingaphinda zisetyenziswe?

Ewe. Iingxowa zokucoca inayiloni zibonelela ngokuphinda zisebenziseke ngenxa yemesh yazo eyomeleleyo kunye nokucoca lula. Amashishini amaninzi akhetha inayiloni ukonga iindleko kunye nokusetyenziswa kwexesha elide.

Ngaba iingxowa zokucoca i-polyester zikhuselekile ekutyeni nakwizicelo zesiselo?

Iingxowa zokucoca iipolyester zingasetyenziswa ekutyeni nasekulungiseni isiselo. Abasebenzisi kufuneka bajonge ukuthotyelwa kwe-FDA ngaphambi kokukhetha imveliso ethile kwezi zicelo.

Yeyiphi ingxowa yokucoca esebenza ngcono kumaqondo obushushu aphezulu?

Iingxowa zokucoca i-polyester zisebenza kakuhle kwiindawo ezinobushushu obuphezulu. Zimelana nobushushu obuqhubekayo ukuya kuma 250°F. Iingxowa zokucoca inayiloni nazo ziyamelana nobushushu kodwa zilungele ubushushu obuphakathi.

Ndingayikhetha njani ibhegi yokucoca eyiyo kwisicelo sam?

Ingcebiso: Qwalasela uhlobo lolwelo, inqanaba lokuhluza elifunekayo, ukuhambelana kweekhemikhali, kunye nobushushu. Phonononga iinkcukacha zemveliso kwaye udibane neengcali zokuhluza ngezona ziphumo zintle.

Ixesha lokuposa: Dec-05-2025